ANILAM G Code List for CNC Mill Controls like 6000M G-codes initiate motion commands, canned cycles and various machine and CNC functions. More than one G-code may be specified per CNC Fanuc G33 G32 Threading G Code. HAAS mill G code cheat sheet? Posted by 4 years ago. HAAS mill G code cheat sheet? Can any of you guys point me to a good reference for HAAs mill. Functional Reporting Codes — G-codes. G-codes are used to report a beneficiary’s functional limitation being treated and note whether the report is on the beneficiary’s current status, projected goal status, or discharge status. There are 42 functional G-codes that are comprised of 14 functional code sets with three types of codes in each.

Knowing about G Code cheat sheet is important because it will guide you on what you need to do. If you are looking for the template or need accounting assignment help; read on this page to find out more information.

How to do a Cheat Sheet in G Code

It is easy to do a G Code sheet sheet as long as you know the symbols and the words to include. It is better if you use a table in creating so that the information will not be scattered.

Code Description

- G0 Rapid movement

- G1 Coordinate movement

- G2 CW ARC

- G3 CCW ARC

- G4 Dwell S (seconds) or P (milliseconds)

- G10 retract filament according to the settings the f M207

- G11 retract recover filament according to the settings of the M208

- G28 Home all Axis

- G29 Detailed Z-Probe, probes bed at three or more points. Will fail if you have not homed yet

- G30 Single Z Probe, probes bed at current XY location

- G31 Dock sled (Z_PROBE_SLED only)

- G32 Undock sled (Z_PROBE_SLED only

- G90 Use the Absolute Coordinates

- G91 Use the Relative Coordinates

- G92 Set the current position to coordinates the given

Cheat Sheet Template: G Code

Comm. | Description | Parameters | Comment | Example |

G1 | Position Feed [F] | [X/Y/Z/E] | G1 F150 X10 | Controlled Movement |

G4 | Dwell / Wait | Time in ms [P] | G4 P500 | |

G10 | Set Offsets Java 8 update 101 64 bit indir. | Pn [RS] | Set the standby(R) or Active(S) Temp (XYZ not done) | G10 P1 S100 |

G20 | Set units to inch | none | G20 | |

G21 | Set units to mm | none | G28 X Y | |

G30 | Z Probe set at defined position | Pn [X/Y/Z] | G30 P0 X60 Y20 Z0.0 | |

Kmspico office 2019 professional plus download. G31 | Return / set Probe at current position | Z P | Set the Z home value or return current probe value | G31 Z0.75 P596 |

G32 | Multiple Z Probe Auto bed compensation | none | M557 sets up four compensation points | G32 |

G90 | Absolute Positioning | none | G90 | |

Relative Positioning | none | G91 |

Here is another CNC g code sheat cheat that you still need to know. You will be given the codes, the description, example and parameters as well.

CNC G Code Cheat Sheet Template

Codes | Description | Parameters | Comment | Example |

G92 | Set Position to value | [X/Y/Z/E] Val | G92 X5 Y10 | |

MO | Stops everything after buffer is empty | none | MO | |

M1 | Sleep | none | M1 | |

M18 | Disable all stepper motors | none | M18 | |

M20 | List files in gcodes folder of the SD Card | none | M20 | |

M23 | Select file for the printing | filename | M23 print.gco | |

M24 | Start / Resume SD Card Print | none | M25 |

Cheat sheet tips: What You Should Know

There are many things that you should know with G code and some computer cheat sheet tips will be your help. Whenever you will write, you need to sum up the information. You need to make a research for more information. You can also get a help from other people if you are having a hard time.

There you go the vi cheat sheet that will help you and other details that will help you. Make sure that you remember the codes as well as the description for easy understanding.

G And M Code Chart

Use our G Code cheat sheet today!

If you would like to download a copy of this page please visit the cnc store. Standard G M code list download

If you would like to download a copy of this page please visit the cnc store. Standard G M code list downloadHaas G Code Cheat Sheet

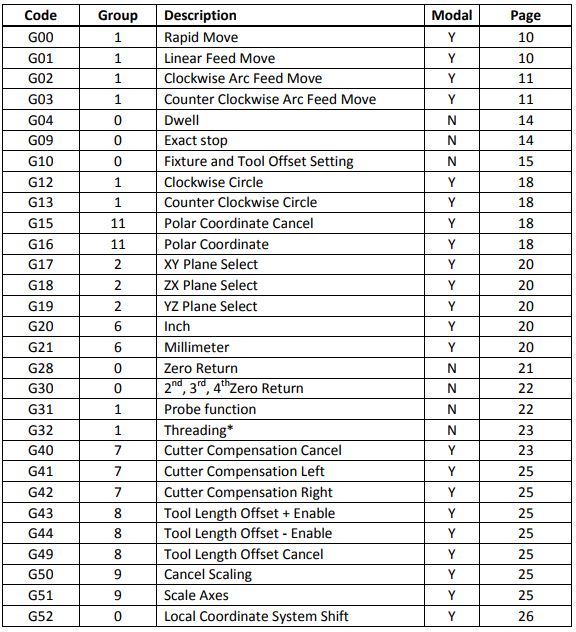

| G-Code List Machining Centers (Common for most machines) | |

| (G-Codes vary from machine to machine) G00 positioning (rapid traverse) G01 linear interpolation (feed) G02 circular interpolation CW G03 circular interpolation CCW G04 dwell G07 imaginary axis designation G09 exact stop check G10 offset value setting G17 XY plane selection G18 ZX plane selection G19 YZ plane selection G20 input in inch G21 input in mm G22 stored stroke limit ON G23 stored stroke limit OFF G27 reference point return check G28 return to reference point G29 return from reference point G30 return to 2nd, 3rd & 4th ref. Point G31 skip cutting G33 thread cutting G40 cutter compensation cancel G41 cutter compensation left G42 cutter compensation right G43 tool length compensation + dir G44 tool length compensation - dir G49 tool length compensation cancel G45 tool offset increase G46 tool offset decrease G47 tool offset double increase G48 tool offset double decrease G50 scaling OFF G51 scaling ON G52 local coordinate system setting | G54 work coordinate system 1 select G55 work coordinate system 2 select G56 work coordinate system 3 select G57 work coordinate system 4 select G58 work coordinate system 5 select G59 work coordinate system 6 select G60 single direction positioning G61 exact stop check mode G64 cutting mode G65 custom macro simple call G66 custom macro modal call G67 custom macro modal call cancel G68 coordinate system rotation ON G69 coordinate system rotation OFF G73 peck drilling cycle G74 counter tapping cycle G76 fine boring G80 canned cycle cancel G81 drilling cycle, spot boring G82 drilling cycle, counter boring G83 peck drilling cycle G84 tapping cycle G85,G86 boring cycle G87 back boring cycle G88,G89 boring cycle G90 absolute programming G91 incremental programming G92 programming of absolute zero point G94 per minute feed G95 per revolution feed G96 constant surface speed control G97 constant surface speed control cancel G98 return to initial point in canned cycle G99 return to Ref point in canned cycle |

| STANDARD G CODE CHART FOR LATHES | |

| (G-Codes vary from machine to machine) G00 positioning (rapid) G01 linear interpolation (feed) G02 circular interpolation CW G03 circular interpolation CCW G04 dwell G07 hypothetical axis interpolation (sine curve) G09 exact stop G10 offset value setting G20 G70 inch data input G21 G71 metric data input G22 stored stroke limit ON G23 stored stroke limit OFF G27 reference point return check G28 return to reference point G29 return from reference point G30 return to 2nd, 3rd & 4th reference point G31 skip cutting G32 G33 thread cutting G34 variable thread cutting G36 automatic tool compensation X G37 automatic tool compensation Y G40 tool nose radius compensation cancel G41 tool nose radius compensation left | G42 tool nose radius compensation right |

| STANDARD M-CODES | |

(M-Codes vary from machine to machine) If you would like to download a copy of this page please visit the cnc store. Standard G M code list download To download chartrs of common Parameter changes and G-codes see below | |